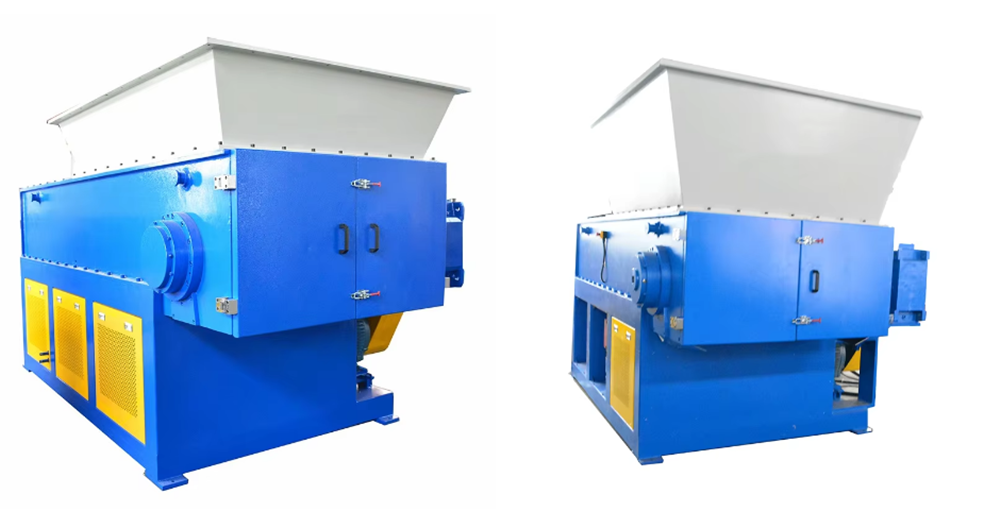

single shaft shredder for shredding waste plastic SKD-II blade

The BE series single shaft shredder is suitable for recycling wide range of materials. It is an ideal machine for plastic, paper, fiber, rubber, organic waste and a wide variety of materials.

single shaft shredder for shredding waste plastic SKD-II blade

Shaft Design | one |

Bearing | Heavy Duty Bearing |

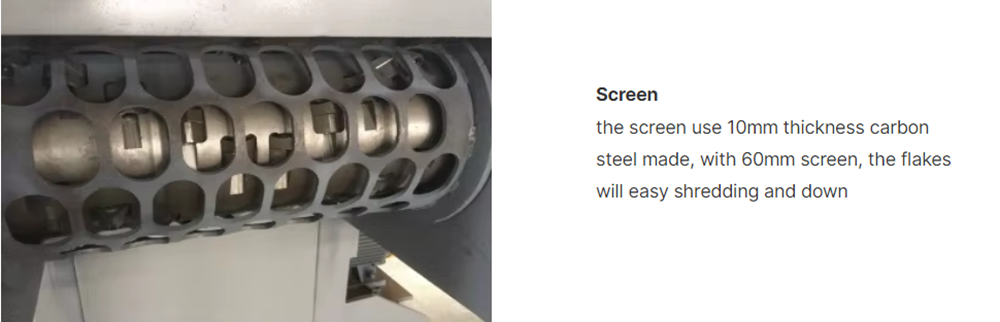

Screen Size | 40-100mm |

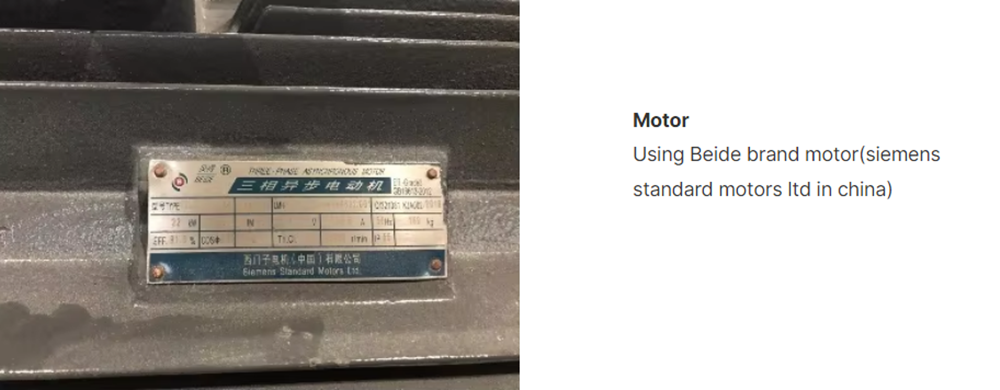

Motor Brand | Simo, Wannan, Siemens, Weg |

Main Motor Power | 75kw |

Gear Box | GUOMAO or BONENG |

Hydraulic Station | 5.5kw |

Main Electrics | Schneider |

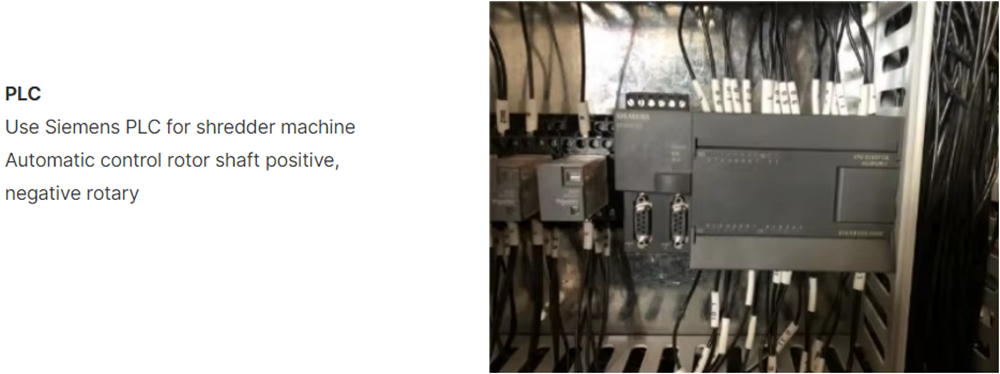

PLC Control | Siemens |

Output | 1500-2000kg/Hr |

Color | customer choice |

After Warranty Service: | Video technical support, Online support, Free spare parts, Field installation, commissioning and Trainning, Field Maintenance and Repair Service |

HS Code | 84778000 |

Single Shaft Shredder Machine

Product Description:

The XR series single shaft shredder is suitable for recycling wide range of materials. It is an ideal machine for plastic, paper, fiber, rubber, organic waste and a

wide variety of materials. As per our customers’ requirements, such as the input size of the material, capacity and the final output size etc, we could work out a

suitable proposal for our clients. After being shredded by the machine, the output material could be used directly or go into the next step of size reduction. With

the function of Siemens microcomputer control system, it is possible to control automatically start, stop, automatic reverse sensors to protect the machine against

over loading and jamming.

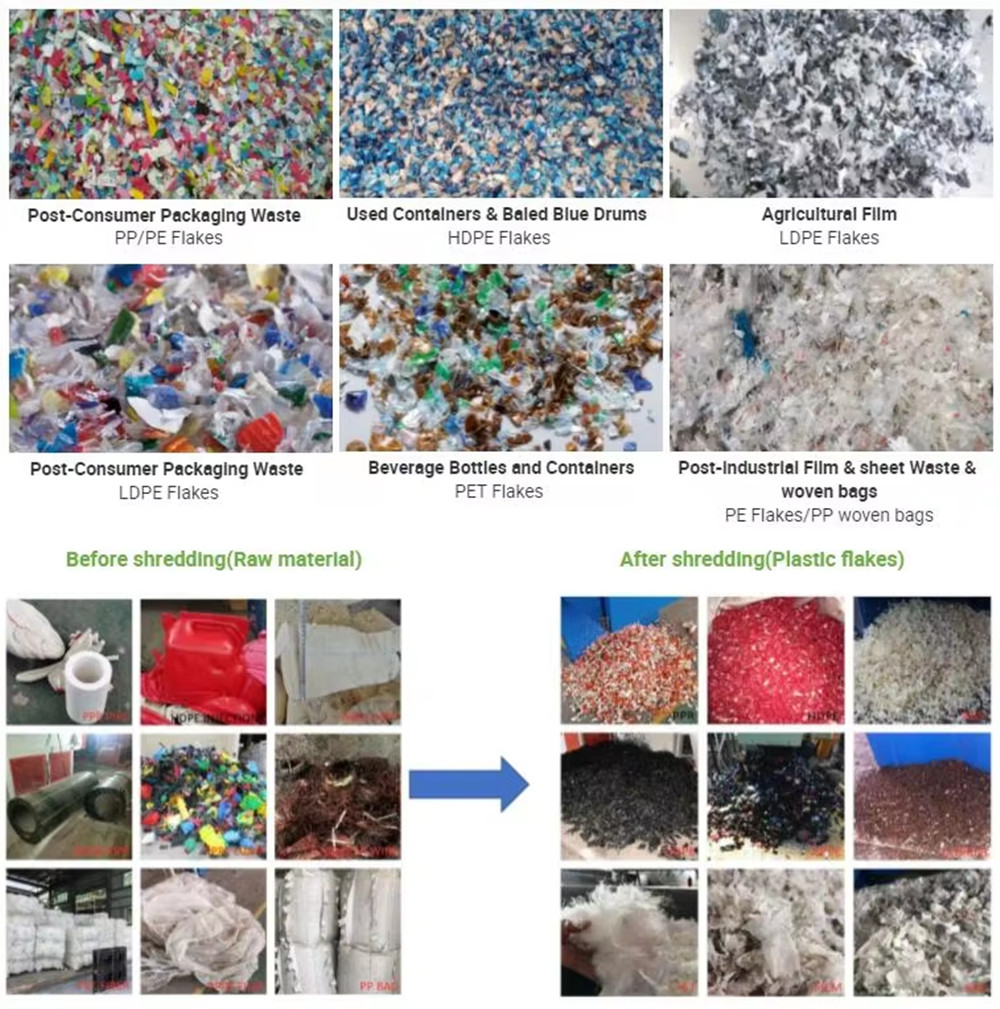

Single shaft shredder machine feature and function: Plastic shredder/shredding machine was mainly used to shred different kinds of plastic materials, especially

very large waste plastic.

single shaft shredder machine can shredding plastic lumps, barrels, pipes , wood, wood pallet, big block material, plastic container, plastic chair , plastic pallet,

woven bags ,jumbo bags, cable tc.

Suitable Products: The single-shaft shredder is used to recycle plastic, paper, wood, fiber, cable, rubber, home appliance, light steel, municipal solid waste, etc.

It is ideally suited for the reduction of a wide range of different materials:

•Refuse-derived fuel: straw, municipal solid waste;

•Textile: cloth fiber, nylon;

•Paper: industrial waste paper, packing paper, cardboard paper;

•Cable wires: copper core cable, aluminum cable, composite cables;

•Polypropylene pipe, industrial packaging & plastic films, PP woven bags;

•Plastic: plastic block, plastic sheets, PET bottle, plastics pipe, plastic container, plastic drums;

Product Parameters:

| |

|

|

|

|

|

|

BE600 | 22 | Φ280 | 75 | 26+4 | 2 | 2.2 | 1550 |

BE700 | 30 or 37 | Φ280 | 75 | 32+4 | 2 | 3 | 1950 |

BE800 | 45 | Φ400 | 75 | 34+4 | 2 | 3 | 3500 |

BE1000 | 55 | Φ400 | 75 | 46+4 | 2 | 4 | 4000 |

BE1200 | 75 | Φ500 | 75 | 68+4 | 2 | 5.5 | 5000 |

BE1500 | 90 or 110 | Φ550 | 75 | 84+6 | 2 | 7.5 | 6200 |

BE2000 | 132 or 160 | Φ600 | 75 | 112+6 | 2 | 11 | 7800 |

Note: The above technical parameters is only for your consideration, real technical parameters of shredder machine will be different based on shredding different

material requirements, please call us for more information before purchasing.

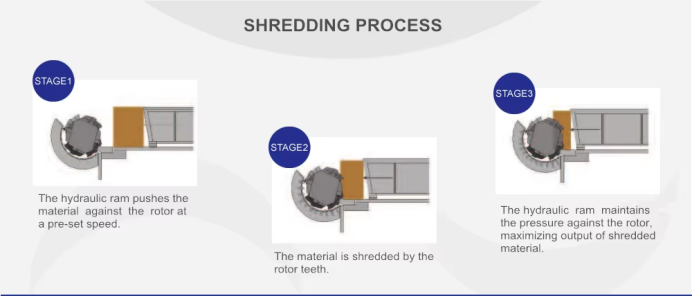

Single Shaft Shredder Machine Work Process:

Service Before Sale <span data-spm-anchor-id="a2700.details.0.i48.23d651daHsUtKq" style="box-sizing: border-box; border: 0px; --tw-border-spacing-x: 0; --tw-border-spacing-y: 0; --tw-translate-x: 0; --tw-translate-y: 0; --tw-rotate: 0; --tw-skew-x: 0; --tw-skew-y: 0; --tw-scale-x: 1; --tw-scale-y: 1; --tw-pan-x: ; --tw-pan-y: ; --tw-pinch-zoom: ; --tw-scroll-snap-strictness: proximity; --tw-gradient-from-position: ; --tw-gradient-via-position: ; --tw-gradient-to-position: ; --tw-ordinal: ; --tw-slashed-zero: ; --tw-numeric-figure: ; --tw-numeric-spacing: ; --tw-numeric-fraction: ; --tw-ring-inset: ; --tw-ring-offset-width: 0px; --tw-ring-offset-color: #fff; --tw-ring-color: rgba(59, 130, 246, .5); --tw-ring-offset-shadow: 0 0 rgba(0,0,0,0); --tw-ring-shadow: 0 0 rgba(0,0,0,0); --tw-shadow: 0 0 rgba(0,0,0,0); --tw-shadow-colored: 0 0 rgba(0,0,0,0); --tw-blur: ; --tw-brightness: ; --tw-contrast: ; --tw-grayscale: ; --tw-hue-rotate: ; --tw-invert: ; --tw-saturate: ; --tw-sepia: ; --tw-drop-shadow: ; --tw-backdrop-blur: ; --tw-backdrop-brightness: ; --tw-backdrop-contrast: ; --tw-backdrop-gray

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Kevin Dong

Phone: 86-13584427912

E-mail: info@bemachine.cn

Whatsapp:+86 135 8442 7912

Add: Jiangsu Province,Zhangjiagang City, Leyu Development Zone,